Performance Trends, Inc.

Producing Quality Computer Tools for Racers and Engine Builders since 1986

Re: Performance Trends Newsletter (updates)

To: Visitors to Performance Trends Website

Subject: Product News/Updates, January 2023

Re: Performance Trends Newsletter (updates)

To: Visitors to Performance Trends Website

Subject: Product News/Updates, January 2023

![]() to

visit our www.performancetrends.com

home page

to

visit our www.performancetrends.com

home page

![]() to

visit our

to

visit our  facebook page and "like" us.

facebook page and "like" us.

-------------------------------------------

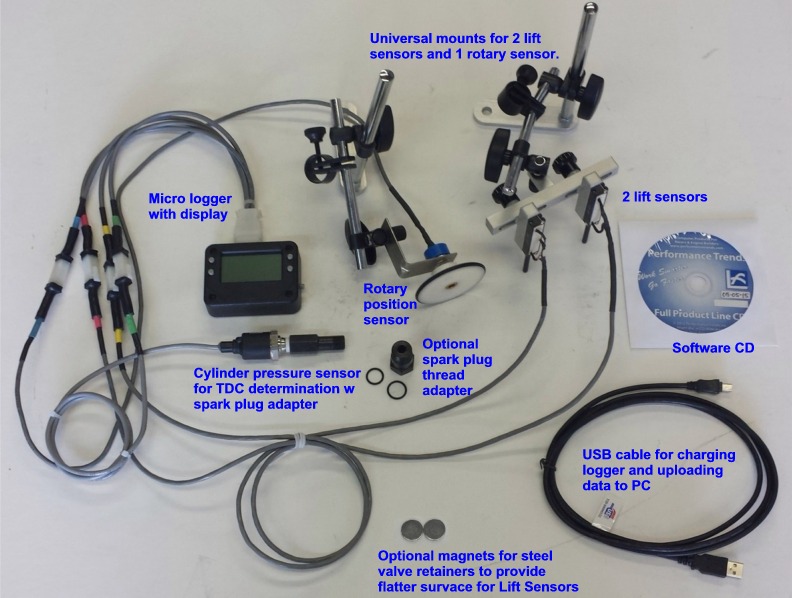

1) Quick Cam Checker Track Tech Results: Our Quick Cam Checker is designed to give you a quick idea of the cam in the engine while it is in the car. Install some sensors and spin the motor over with the starter and you have a good idea how big the cam is. Well, track tech inspectors got wind of it and adapted it to teching engines after a race. The largest sales have been to techs for the GM 602 and 604 "sealed" crate motors.

Standard Quick Cam Checker System

Special 602/604 Bracket for Lift Sensors

Chad Smith, a licensed IMCA tech inspector, was good enough to share many of his data files and experience with us. Here's some screen captures from Chad's results with some explanations. Note that some records were not of 604 Crate Motors, and have been crossed out in blue in the table. We have also shrunk down the first column with "Record" names like engine #, racer name, etc to protect people's privacy. Typically this column is wider to display it's info clearly.

With his experience, Chad developed his own 604 Baseline from one of his tests, run #12. He said it agrees better with other legal engines he's tested than the 604 baseline provided with the Quick Cam Checker software. Here's a graph comparing his Baseline to the 604 Baseline provided in the QCC software. You will notice his Baseline's lift is slightly less and both lobes are slightly retarded.

Here's 3 typical comparisons of cams that passed tech inspection (the red and blue graphs) graphed over his typical baseline in black. The first graph shows where the Run Number is so you can refer to the table if you want exact durations, lifts, centerlines, etc.

Here are 2 graphs for a cam that did not pass tech inspection. These are 16 and 17 in the table. Runs 14 and 15 were also done of this same cam. The cam was pulled and tested on a complete cam test stand and verified to be out of spec, and the racer disqualified.

Runs 9, 10, and 11 of another engine raised some eyebrows, but not to the point of pulling the cam for further testing.

![]() for more info on

our Quick Cam Checker.

for more info on

our Quick Cam Checker.

-------------------------------------------

2) DataMite Electrical Noise We've always known that electrical noise from the ignition, certain light fixtures, VFD motors, etc can cause noise in the DataMite data. This shows up as some extreme jumps in data, say for head temp that reads about 200 degrees to read 0 or maybe 1200 degrees for a couple of data points. Here's an example of noise on an RPM channel, where the real RPM is between 800 and 1600 RPM. But there are noise spikes jumping to over 10,000 RPM.

The DataMite software can typically find these noise spikes after the test and edit them out, as shown below.

Well, we've just leaned that this "noise" can also cause the DataMite to not sample at the correct rate. Say the DataMite is set to sample at 50 times a second, that is every 0.02 seconds, or 20 milliseconds. If there is a lot of electrical noise, the DataMite may sample at every 20 mSec for most data, but perhaps 21 or 22 mSec at other data points. This is typically not a big deal, unless you are measuring acceleration rate, like with an inertia dyno. If the time is not what we expect it to be, acceleration will be wrong and torque and HP from an inertia dyno will be wrong.

Here's a graph of back to back inertia dyno runs, one with no noise and the other with noise which shows faster acceleration and therefore more torque and HP. You will notice the noise effect started at about 5800 RPM.

In Dyno DataMite v4.2 A.062 we have now added a check in the software to see if the sampling rate is consistent and accurate. If we detect a problem, we will give you an error message like that below when you first upload a test to your PC.

This message is very helpful for troubleshooting the source of electrical noise. For example for troubleshooting the dyno producing the graphs above, we would get this message uploading a test with the engine not even running. They were also having trouble with their DataMite 4 not connecting to their PC. It seemed to connect only half of the time.

We would record about 10 seconds of data, and see if the message above would pop up, and it did. Then we disconnected most all sensors and recorded 10 seconds of data again, and the message did not appear. Then we plugged sensors back in 3 or 5 at a time to narrow down the source. It turned out to be 2 of the EGT probes which were bringing in electrical noise from an electric pump motor. Their thermocouple extension cable was running close to an electric conduit.

Before we had this software check, all we knew was that some tests produced different power when they should be the same, and we did not know which data was correct.

If you own v4.2 software, this is a free update. If you own earlier software than v4.2, there will be a charge to update.

![]() to install this latest version right over the top of your existing

v4.2. When the installer asks, select to do a Refresh installation

instead of a Complete (typical) installation. This will keep your

configuration, preference settings, history log, etc. all intact.

to install this latest version right over the top of your existing

v4.2. When the installer asks, select to do a Refresh installation

instead of a Complete (typical) installation. This will keep your

configuration, preference settings, history log, etc. all intact.

![]() to email us about the cost to update your older software.

to email us about the cost to update your older software.

-------------------------------------------

3) Last December's Newsletter Here are the topics covered in our previous newsletter. If you would like another copy of December 2022's newsletter (or any previous newsletter) for detail on these topics, visit our website at: Performance Trends Newsletters

Performance Trends reserves the right to discontinue, update, or modify its product line and pricing at any time.