Mechanical Components of an

Inertia Dyno

Finally we can begin to talk about the components of the Inertia Dyno

This system can and is entirely safe if do correctly, but there are

some things to watch for,

Please read the following carefully........

Flywheel

Warning!!!!! Due

to the size/weight of the flywheel needed, and the speed that it needs

to turn, EXTREME care must be taken in its construction. Failure to do

so can and will result in major damage to you, your property and the property

of others, personal injury and possibly death!!

This is entirely up to you, if you do not feel comfortable at this

point, turn back now. Neither TDKMotorsports nor any of our associates

will be held liable for damages caused by the use of the following information.

WARNING WARNING WARNING WARNING

WARNING WARNING

Please use some common sense in

the construction of a dyno, your life will depend on it!!

(The following is an example of what not to do.)

Recently...

It has come to our attention that someone has built dyno using a flywheel

made from railroad car wheels. This in itself is not all wrong, assuming

of course they are properly balanced etc.

However, connecting them to an engine in a direct drive configuration

and spinning them to 6000 rpm!!!!! is NOT a good design.

Remember the laws of physics still apply and

at this RPM there is a very real chance of the flywheel becoming a bomb

by exploding due to centrifugal force. Please see the warning below for

more information.

Please use a bit of common sense and if you

have ANY doubts as to the suitability of your design PLEASE contact us

first.

WARNING WARNING WARNING WARNING

WARNING WARNING

This is serious business, the flywheel you need is going

to be approx. 2 ft+ in diameter, 1" thick and weighs 135lbs+, spinning

at 2000 rpm or more. If it should fail in any way, it can and will cause

serious damage! This can be done safely, however if you try to use some

egg shaped piece of steel, strap it to an axle, and spin it 5000 rpm ...

The authorities may never find you or it again! Please use some common

sense, the construction of this flywheel is best farmed out to someone

who can do it right. (call in all the favors from buddies who may be in,

or have contacts in the machinist business) It must be perfectly round

and balanced, it must have a center hub securely welded in, and keyed to

the axle. Do not attempt to balance the flywheel by drilling holes in

it, this only balances it for a given RPM and will also weaken it which

increases your chance for disaster. You must build the frame of the

dyno to include some integral scatter shield in case for some reason there

should be a failure. Remember that you may need to allow for removal of

the flywheel for service at a later date. The flywheel is probably the

one reason, other than the data acquisition system, that people don't build

their own dyno, it can be a little intimidating.

Again, this can be done safely, you just have to be careful.

Here are some of the considerations you need to be aware of:

Size/weight:

We've done some of the work for you here, the wheel that we are using

is 24.5" in diameter 1" thick, weight is approx. 135lbs, made from plain

old hot-rolled steel plate. We got lucky and came across a couple of steel

disks in the scrap yard that were about the right size. We did all the

rest ourselves, cut the center hole, welded in the center hubs with 1.25"

keyed holes, and then spent many hours trying to make it round and balanced.

We wouldn't recommend it to anyone to do, in fact we would pay someone

to do the next one, it was far too much work, and we nearly messed it up

a couple of times. Not having the proper tools to do this it really wasn't

worth the hassle.

Checking some local prices:

Steel: 26" diameter x 1" approx. $85

Weld in center hub and machine round approx. $300

This was quoted from a local shop that is known for being pricey, if

you do some checking you should be able to do better, even at these prices,

doing it yourself really isn't an option for most people. Again, call in

the favors.

(See the FAQ

page for what size wheel you should use for your dyno)

WARNING!!!! It

is possible to spin a piece of plate steel fast enough to for it to burst.

The centrifugal force becomes so high that it exceeds the tensile strength

of the steel and it explodes. BOOM!!! You're dead!! Not a nice thought

but, this is one of the dangers you should be aware of. We have had the

calculations done. We won't tell you what the actual numbers are. However

spinning a 30" wheel to 2000rpm, or a 24-25" wheel spinning up to 3000rpm,

should allow you all the capacity you'll ever need for 20-25 HP, and still

be well within safe limits, again assuming the wheel is perfectly round

and balanced! Choosing a large enough wheel to give you acceleration

times in the 8-12 sec. range is about right.

Safe operation is the responsibility

of the operator/builder. TDKMotorsports will not be held liable for any

damages caused by the use of this information.

More Size/weight:

If you really need to know more than the guidelines given above, here

are the relevant formulas...

The formula for determining the torque is:

Torque = PM * rpm per second / 9.551

where "PM" represents the Polar Moment of Inertia of our inertia dyno's

flywheel.

If you don't know the Polar moment of Inertia for the flywheel (and

your flywheel has a constant thickness cross-section) we can calculate

it with the formula:

PM = (W * r^2) / 32.16 / 2

where "W" represents the flywheel weight in pounds and

r is its radius in feet.

(the formula for weight of a steel disk can be found in the "FAQ" page)

Once you have the torque, it is easy to calculate the horsepower with

the standard formula:

Hp = Torque * rpm / 5252

Keep in mind that the rpm in the last formula must be the average rpm

during the sampling period.

Say our example uses a 10 pound flywheel, 8" in diameter (thus it would

have a Polar Moment of Inertia of .017 foot-pounds-second^2). If the engine

was able to accelerate this flywheel from say 4,800 rpm to 5,200 rpm in

2/10 of a second (a rate of 2,000 rpm per second) that would represent

a torque of 3.6 pound feet. Since our above example had an average rpm

of 5,000, it produced 3.4 Hp during the test.

If you have any questions about using this formula feel free to

contact: TDKMotorsports

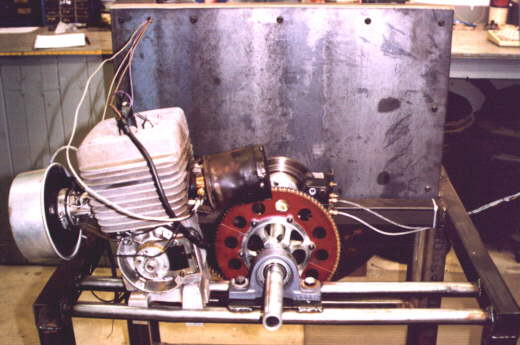

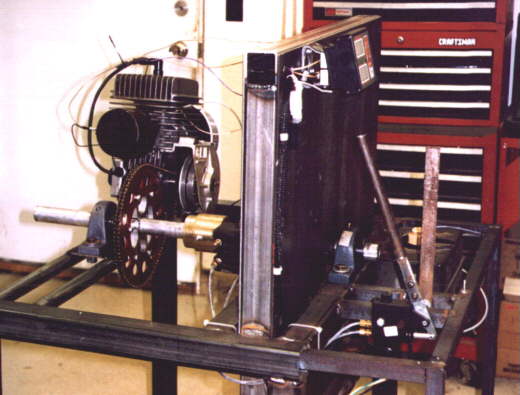

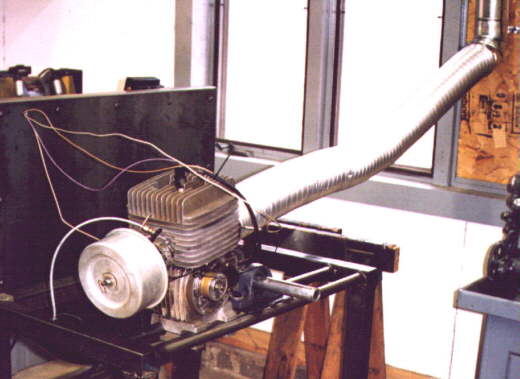

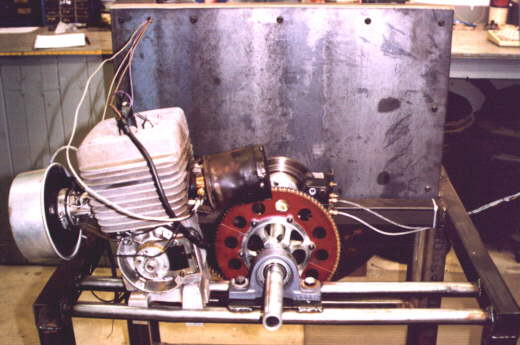

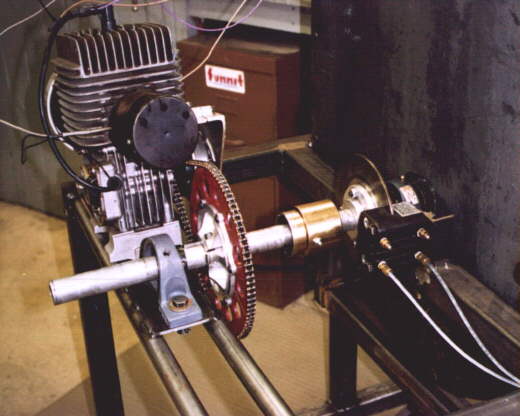

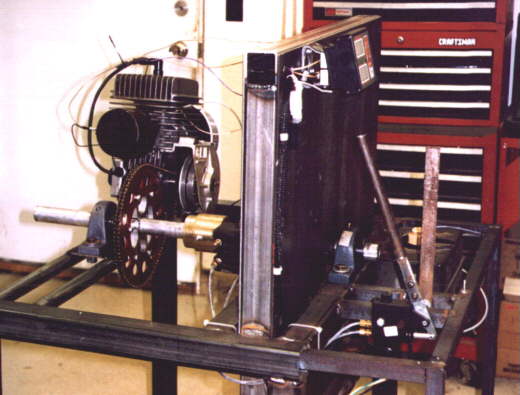

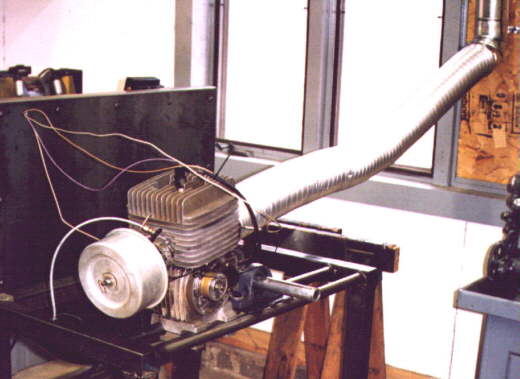

Finally some pictures of what we've been talking about........

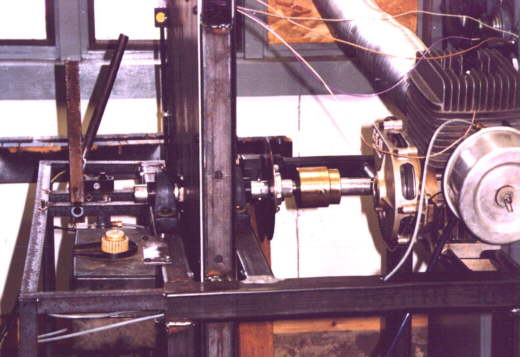

Pictures showing heavy duty scatter shield to contain any disasters,

which might occur.

Frame

Here is one place where a picture is worth a thousand words, or absolutely

nothing. The pictures will give you a general idea, but the actual configuration

is up to you.

Here are a few considerations:

1. Make it sturdy, weld all joints. 2" x 2" x .095 works great.

Single cylinder engines produce an amazing amount of vibration, you don't

want it to shake apart.

2. Build the frame in such a way that it will allow easy access

to the motor.

3. Make everything as close to a regular kart configuration as

possible, this makes it easier to take the motor off the kart and mount

it on the dyno.

4. Put some rubber castors on the bottom so it can be easily

parked in the corner when your not using it, also helps to absorb some

of the vibrations.

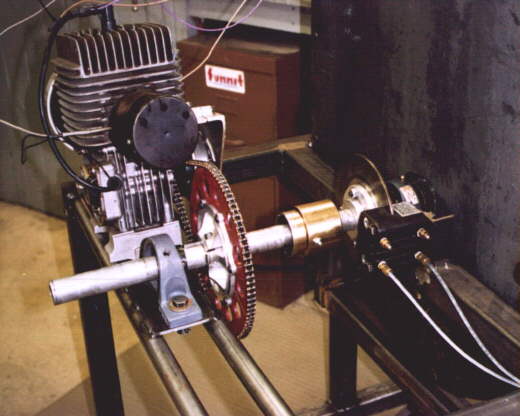

Axle assembly

Use standard kart pieces here as much as possible, makes it easy to

integrate everything together. Otherwise nothing fancy.1.25" kart axle,

sprocket hubs, brake rotor, etc. The only exception is using cast iron

pillow block bearings, just because they were easy to bolt down to the

frame. You may want to get an extra sprocket hub to make it easier to swap

between motor types.

The portion of the axle that goes through the flywheel and flywheel

bearings is recommended to be solid.

Brakes

Kart type brakes are normally sufficient unless you intend to pull the

motor against the brake in an attempt to build heat. If that is the case

you may want ventilated or dual rotors. Slowing the flywheel is the only

other purpose here. Listening to the flywheel spin itself down gets really

irritating! We once let it do this by itself, would you believe it spun

for 8 minutes and hadn't stopped yet! Attempting to stop the flywheel too

quickly with a large brake can cause the entire dyno to try to tip over.

Remember though, all these components contribute to the "inertia weight"

which can mess with the accuracy, especially if you change something mid-stream.

One-way clutch

THIS IS VERY IMPORTANT!! After the

flywheel/engine has been accelerated and the throttle is closed the flywheel

will want to continue to rotate at high rpm and decelerate very slowly

(see above), while the engine will attempt to slow much quicker. When this

happens the engine becomes the brake for the flywheel. This "engine braking"

is very hard on your engine, the vacuum caused by the throttle being closed

places the connecting rod and piston in "tension", they are being "pulled"

instead of "pushed", exactly the opposite of what they were designed for.

Stresses on these parts can be as much as 200-500% higher than normal during

this "engine braking" period. Also remember 2-cycle engines are getting

no oil when the throttle is closed. A brake on the flywheel is not fast

enough. A centrifugal engine clutch doesn't work very well here either,

remember the flywheel is doing the driving, all the pieces in the clutch

stay locked as long as they are all spinning at the same speed. (until

the clutch assembly slows to below stall speed) You can try it without

if you want, but it's not a pretty deal. We did alot of searching here,

several options were looked at. There are available, some one-way bearings

that would work great for this, just like the ones in an electric starter

drive. The problem is, by the time you get a bearing that will handle the

torque load and abuse of a single cylinder engines alternating power output

(one of the most harsh things you can do according to the "power drive"

industry, they step up the size of components by about 30%+ if they are

used on a single cylinder engine) you get into some expensive pieces. We

found one piece that would have worked great, it had an 11/4" keyed hub

inside and a "bolt on" flange for sprockets on both sides, really cool!

The price was nearly $500! Not an option as far as we were concerned! We've

been told that a kart style axle clutch would work here, but haven't gotten

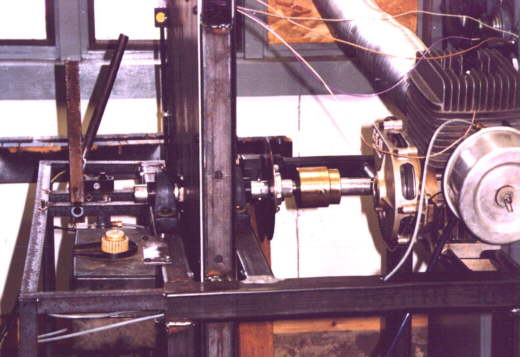

hold of one to try. Looking at the pictures, you'll see a small gold colored

deal between the sprocket hub and the brake rotor. This is our solution.

It's an adapted piece of farm equipment. (Hey, we're farm boys!) It has

some limitations, but it was cheap! It needed a small amount of machine

work first but works great.

Info added by Performance Trends, Nov 2,

2017: Check the last page (FAQ page) for this TDK website more info on the

one-way clutch.

Picture of one-way clutch after machining........

Update Sept-2004:

These clutches are very simple but have proven very reliable. Many

dyno builders are reporting literally thousands

of runs with no failures.

I can make one of these clutches for anyone who cannot find one

or cannot get the machining done themselves.

They are done on a "made to order" basis to fit your specific application

however.

Price is $140 including shipping.(Must be pre-paid)

Picture showing one-way Clutch, Brakes, and axle assembly

Engine Clutch

An engine clutch is used simply for ease of starting etc. Direct drive

was attempted, but just didn't work out real well. The engines were hard

to get started because we were trying to "start" the flywheel at the same

time, the engine would start and have to accelerate the flywheel while

trying to get to an idle. Putting a clutch on works much better. The only

thing you have to do is set up a clutch for very low engagement in order

to be able to accelerate the motor through the entire power band, before

and after the torque peak. A Yamaha clutch set to stall at approx. 6000rpm,

and a Briggs clutch at approx.2000rpm are used now and work quite well.

Now the engine can be started, warmed up, etc. When doing a "run" the engine

is brought up to the clutch rpm, the flywheel is allowed to catch up so

everything is locked together, then the throttle is opened form there.

Gauge

The data acquisition system is capable of recording and displaying CHT

and EGT "live" depending on the configuration(optional hardware),however

if you do not have this capability you'll need something.

We use a Digatron off of a kart to monitor these in real time. You

can use one from your kart or used ones can be had a swap meet very reasonable.

That should about do it for the pieces-parts explanation, take a look

at the pictures for ideas on throttle controls, fuel tanks, etc.

Sorry the dyno isn't real pretty. Since we got it all working, we've

been USING it, and haven't had time to tidy it up much.

Update Sept 2004

Unfortunately (or fortunately, depends on your point of

view) my dyno still looks like this today.

I didn't build it real pretty originally because I wasn't really sure

it was going to work...........

Now, it works so well I haven't had any reason to take it apart and

"pretty" it up. NOTHING has been changed on it since it was built.

More pictures

Back

HomeNext

Contact us at: TDKMotorsports

This is an informational site about

the construction of a prototype Inertia dyno. Large metal objects spinning

at high speeds are very dangerous and may cause severe injury or death.

TDKMotorsports will not be held responsible for any damages to you or your

property due to your use of the information provided on this site. By using

this information you assume all responsibility for any loss or damages

incurred.