Performance Trends, Inc.

Producing Quality Computer Tools for Racers and Engine Builders since 1986

Cam Test Stand for Cam Analyzer

Electronics and Encoders for Recording Cam Lobe Measurements

As Seen on TV's Motorhead Garage

![]() to view clip of show

to view clip of show

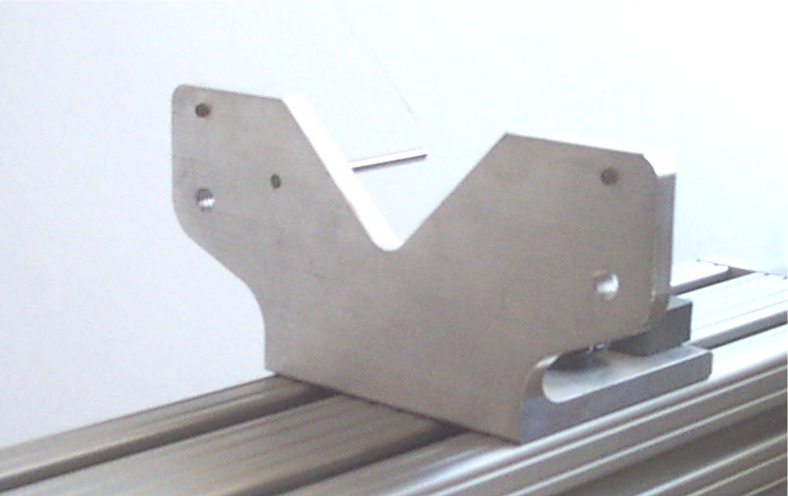

Our Cam Test Stand is shown below. It's encoders measure lift to .00004 inches (4 hundredths of one one thousandth of an inch) and cam rotation angle to .05 degrees.

Standard "non-motorized" Stand w

V

Blocks

Motorized Cam Test Stand mounts cam "on centers"

New USB Logger Nov, 2020

![]() to view the Cam Analyzer software page, the

software which runs the Cam Test Stand.

to view the Cam Analyzer software page, the

software which runs the Cam Test Stand.

![]() for

one customer's experience where measuring a new cam saved a lot of time,

money and confusion. We've had lots of customer's relay similar

stories, but Mark put "pen to paper".

for

one customer's experience where measuring a new cam saved a lot of time,

money and confusion. We've had lots of customer's relay similar

stories, but Mark put "pen to paper".

Displayed below are 3 screens showing some of the features of the Cam Analyzer when fitted with our Cam Test Stand.

Main Screen when measuring a lobe. Note that on the main screen, the layout of the cam is displayed so you know exactly which lobe you should be on for the different cylinder numbers, intake and exhaust. Also note that the lobes are graphed immediately with each measurement so lobes which are "out of line" can be quickly checked again.

This comparison report shows critical data for each of the 16 lobes on this cam.

(Click on image to enlarge it)

(Click on image to enlarge it)

This graph shows detailed comparison between all lobes on this cam. You can select to graph only certain lobes or all lobes, and lobes from other cam tests. You can also select to graph lift, velocity, acceleration, and/or jerk.

(Click on image to enlarge it)

(Click on image to enlarge it)

Plus Version of Cam Analyzer

The Plus Version of the Cam Analyzer adds "high tech" several features to our standard program. Prior to version 3.8, most of these features were only useful if you have the complete Cam Test Stand. Now with version 4.3, you can use these features on hand measurements (dial indicator and degree wheel), standard profiles created within Cam Analyzer, and from importing several formats of standard cam files (like Cam Dr tm, Cam Pro Plus tm, S96, Andrews, Comp Cams, Doctor Dr, .svl, .p). These Plus features include:

- Virtual Follower

- Graph Analyze - Find Difference Between Lobes

- Lobe Runout Measurement

- Minimum Required Flat Tappet Diameter Calculation

- Comparison Reports, between different cam files (camshafts)

- Cam Card report

- Indexing the rotary encoder based on dowel pin or keyway location

- Measure lobe Asymmetry

- 4 more detailed analysis reports

- Lobe Analysis Report (similar to Don Hubbard's C-PEP report from his "Camshaft reference Handbook")

- Custom Duration Report, and you can include Asymmetry and Overlap

- Seating Velocity Report

- Checking Limits Report

- You can Advance and Retard the cam data after it has been measured

- Watch an animation of the Virtual Follower to see the contact points move, instantaneous Rocker Arm Ratio, etc.

- More Advanced Options for special lobes, like lobes with 2

"bumps" or where you want to view base circle measurements, runout,

etc.

for info on "2 bumps" option measuring a Briggs & Stratton

cam.

for info on "2 bumps" option measuring a Briggs & Stratton

cam.

![]() for complete user's manual PDF, where Plus Features are described in

Appendices 4, 5, 6, and 8.

for complete user's manual PDF, where Plus Features are described in

Appendices 4, 5, 6, and 8.

Virtual Follower

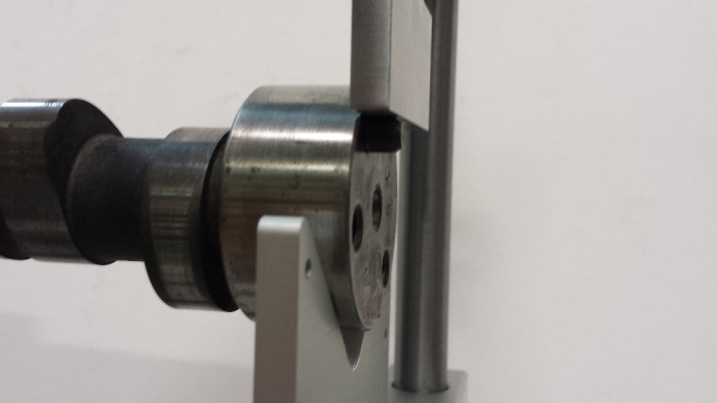

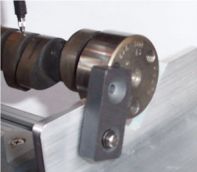

The Virtual Follower feature lets you measure the cam on the stand without using the actual follower used with the cam. You will place the linear encoder's pointer directly on the lobe. See Figures below. The advantage is you don't need the actual follower or the bore adapter of the correct size for the follower. For some valve trains, like Overhead Cam systems with Rocker Arms, the Virtual Follower method is the only method available without installing the cam in the engine or Head.

Using Actual

Follower

Using "Virtual" Follower

V4.0 lets you use most any roller follower, including

with encoder

pointer

the .750" diameter Universal Roller, pn: CTSUR750

![]() for a graph showing

the significant difference (error) between measuring the lobe with the pointer

only, and how the Virtual Follower simulation converts this data into the true

Cam Profile.

for a graph showing

the significant difference (error) between measuring the lobe with the pointer

only, and how the Virtual Follower simulation converts this data into the true

Cam Profile.

You will enter the measurements for the flat or roller follower, or overhead cam valve train into the program. The software will calculate the resulting valve lift, instantaneous rocker arm ratio, contact point on the follower, and much more. The Virtual Follower feature is currently developed for:

- Flat Tappet Followers (which includes Overhead Cam Direct Acting "Buckets")

- Roller Followers

- Overhead Cam Center Pivot Rocker Arm (input screen shown below)

- Overhead Cam End Pivot Rocker Arm (finger follower, input screen shown below)

(Click on images to enlarge them)

(Click on images to enlarge them)

You can select to use the same or different Virtual Followers on the intake versus the exhaust cam lobes.

Accuracy of Virtual Follower

The graph below indicates the typical accuracy of the Virtual Follower to simulate the actual follower for lift and acceleration. (Acceleration was included as it magnifies differences between lobes.) Note that we could have come up with graphs of better accuracy. We purposely used typical data to show that there will always be some difference between the Virtual Follower results and results measured with the actual follower.

![]() for a "Graph Analyze - Find Difference Between Lobes" report showing the

maximum difference found between these 2 cam measurements (Actual and Virtual

Follower).

for a "Graph Analyze - Find Difference Between Lobes" report showing the

maximum difference found between these 2 cam measurements (Actual and Virtual

Follower). ![]() for a "Lobe Comparison" report showing the difference between these

measurements for Tappet Lift, Duration, Lobe Separation, etc. For most of

these critical measurements, the difference is less than 0.5%. For less

critical measurements, like peak accelerations, the difference is typically

within 2% to 5%.

for a "Lobe Comparison" report showing the difference between these

measurements for Tappet Lift, Duration, Lobe Separation, etc. For most of

these critical measurements, the difference is less than 0.5%. For less

critical measurements, like peak accelerations, the difference is typically

within 2% to 5%.

(Click on image to enlarge it)

Graph Analyze - Find Difference Between Lobes

If you graph 2 cams, an Analyze option is available called Find Difference Between Lobes. This option will automatically advance or retard each corresponding lobe of the second cam to obtain the best match, and then display the max difference between the lobes and how much advance and retard was required. If you have graphed Lift, then the best match for Lift will be found and the max difference in Lift will be displayed. If Velocity and Acceleration are graphed, then the best match for both Velocity and Acceleration will be found and the max difference in Velocity and Acceleration will be displayed.

This feature is very useful for finding how a particular cam has changed

after running in the engine, if a cam is within legal specs for some racing

class, or how similar 2 different cams are. ![]() to see a typical "Find Difference Between Lobes" report for

Lobe Lift only for all 16 lobes.

to see a typical "Find Difference Between Lobes" report for

Lobe Lift only for all 16 lobes. ![]() for a comparison of only 2 lobes, #1 Intake and

Exhaust Lobe Lift and Acceleration.

for a comparison of only 2 lobes, #1 Intake and

Exhaust Lobe Lift and Acceleration.

Indexing the Rotary Encoder

When you measure a cam on the Cam Test Stand, you must choose where the #1 Intake cylinder's lobe will be installed in the engine, typically based on Intake Lobe Centerline. All cam data is accurately measured (duration, lobe separation, lift, overlap, accelerations, etc) and the differences between lobes are identified. However, you would not know if the cam would get installed at this Intake Centerline unless you verified it in the engine.

Note: With redesigns in the Cam Test Stand, the "TDC Checking Bridge" has now been replaced by the much more compact "Narrow Universal Flat Follower", but the process is much the same.

Now we can measure the dowel pin or keyway location of a cam and know how it

is timed in the engine, assuming standard, production timing in the gears.

Using our TDC Checking Bridge, we can precisely measure the dowel pin or keyway

location. Then, knowing how many degrees CW or CCW from TDC it is designed to

be, we can index the rotary encoder precisely. Using this method we can

index the cam to better than 0.5 degrees. (We can provide the

"degrees CW or CCW from TDC" data required for this method for many popular engines, but not

all engines.) For engines for which we don't have this data, you may have

to work out these settings from known cams.

(Click on images to enlarge them)

(Click on images to enlarge them)

The TDC Checking Bridge is sold as an accessory, and adjusts to most any length cam from 12 inches to 24 inches in length (measured from first and last journal bearings). However, you do need the Plus version of the software to access this feature. Longer Bridges are available at an additional cost.

Other Plus Features

Runout is the variation in the base circle radius, where a lower value indicates a higher quality cam. The Minimum Required Flat Tappet Diameter Calculation is an accepted equation based on peak velocity, where larger velocities require a larger flat tappet follower diameter.The Cam Card report displays

critical, measured cam results commonly found on a cam grinder's cam card, shown

below:

(Click on image to enlarge it)

(Click on image to enlarge it)

New Cam Card Options in v4.0

(Click on image to enlarge it)

(Click on image to enlarge it)

Asymmetry Calculation:

More Report Types:

![]() for: Custom Duration (duration, opening, closing, asymmetry at most any cam

or valve lift)

for: Custom Duration (duration, opening, closing, asymmetry at most any cam

or valve lift)

![]() for: Seating Velocity (valve closing velocity at user specified RPMs to

help pick valve Valve Lash)

and estimated lash point

for: Seating Velocity (valve closing velocity at user specified RPMs to

help pick valve Valve Lash)

and estimated lash point

![]() for: Checking Limits (compare a measured lobe to up to 12 specified limits,

like duration at various lifts, lobe separation, max lift, etc.) "Checking Limits" report makes it quick and easy to

check if cams are legal for restricted classes of racing, or are meeting

certain quality control limits.

for: Checking Limits (compare a measured lobe to up to 12 specified limits,

like duration at various lifts, lobe separation, max lift, etc.) "Checking Limits" report makes it quick and easy to

check if cams are legal for restricted classes of racing, or are meeting

certain quality control limits.

Cam Grinder Version of Cam Analyzer

The Cam Grinder version is new for v4.0, and adds several features beyond what the Plus version does. It's features are specially designed for customers who typically grind cams or need to send files to cam grinders for special custom grinds. The Cam Grinder version also gets into more detailed analysis than the typical customer may need. These include:

- Measure cam lobes and keep their absolute timing, and not adjust for lifter bore angle, firing order, etc. It keeps the absolute timing as is present on the actual camshaft, which is more useful to cam grinders. See picture below.

- You can measure absolute lift of the lobes (which will include base circle and runout) and journals if you choose.

- You have many more graphing options and graph data types, including:

- Absolute Lift (This is lift measured from the center line of the cam. If you have a 1.100" diameter base circle and a .400" max tappet lift, you should see approximately .550" of lift on base circle and .950" (.550" + .400") of lift at max lift.)

- Thrust Angle (For a roller cam, this is the angle the contact force is acting on the follower, typically putting some amount of side loading or thrust on the follower.)

- Contact Point (How far from center of the follower has the contact point moved.)

- Radius of Curvature (The radius of curvature at this particular point on the Actual Cam Profile.)

- Raw Cam Data as Measured (This is what the linear encoder measured.)

- Actual Cam Profile (This is what a "knife edge" pointer would have measured. This is the "Raw Cam Data as Measured" but correcting for the radius of the pointer which was doing the measurements. This should be what a cam grinder would have for a design file.)

- Lift Frequency Analysis *

- Acceleration Frequency Analysis. *

- Jerk Frequency Analysis *

* These Frequency Analysis graphs can be done either vs Order Number or RPM Based on the Natural Frequency of a valve spring. The specs for the Natural Frequency of the Valve Spring are contained in the Test/Cam Setup Screen. See picture below.

- Import X and Y data, or polar data (radius, and either radians or degrees) to generate a cam file.

- Input and calculate a valve spring's natural frequency.

- Export a Manufacturing type data file.

- Special Edit and Export Filtering options.

- Include a "Test Piece Picture File" in the test, like a picture

of the cam or other valve train part. This picture can be included in

printouts of the graphs and reports.

Main Screen Graph showing absolute timing

(Click on image to enlarge it)

(Click on image to enlarge it)

Graph showing absolute timing and absolute lift for lobes and journals,

viewed from end of cam (polar coordinates)

(Click on image to enlarge it)

(Click on image to enlarge it)

Graph showing journals with difference exaggerated, viewed from end of cam

(polar coordinates)

(Click on image to enlarge it)

(Click on image to enlarge it)

Cam Grinder Frequency Analysis

(Click on image to enlarge it)

(Click on image to enlarge it)

Cam Grinder Graph Options

(Click on image to enlarge it)

(Click on image to enlarge it)

Cam Grinder Edit Duration Option (figures show increasing durations 15% for

intake and exhaust)

(Click on images to enlarge them)

(Click on images to enlarge them)

Printouts including the Test Piece Picture (page from user's manual)

click image to enlarge

click image to enlarge

![]() for complete user's manual PDF, where Cam Grinder Features are described

in Appendix 6, 7 and 9.

for complete user's manual PDF, where Cam Grinder Features are described

in Appendix 6, 7 and 9.

What You Get:

- Cam stand with adjustable V blocks. 32" length is standard to accommodate cams up to approximately 27-28" long.

- Sliding bracket holding vertical bar holding lifter bore bracket and linear encoder bracket (bar is notched to keep all brackets centered over the cam).

- Linear Encoder with sliding adjustable bracket.

- Lifter bore * and bracket (attaches to Linear Encoder bracket).

- Rotary Encoder with mounting magnet, sleeve and positioning rod.

- DataMite Minu USB data acquisition.

- USB Cable, which provides both data communications and power.

- User's manual.

- Software CD.

- EZ Start Guide.

* Lifter bore is bored to user's requirements for their lifter size, .842" GM is standard. Additional Lifter bore sleeves for different size lifters available at additional cost.

The CTS-WOS (Cam Test Stand without the Stand) consists of item 3 encoder but without the bracket, item 5 encoder but without the mounting parts, and items 6-10.

Accessories:

New Style V Block

(2010)

Old Style V Block (pre 2010)

Part of Part Number: CTS-UK Cam Test Stand Update Kit to

bring older CTS up to our current design. This change allows the

linear encoder bracket to slide past the V Block to measure position of keyways

and dowel pins.

indexing grove on the vertical rod and the indexing thumb screw on the CTS-UFH which seats in the groove to keep perpendicular to the cam axis. Note: This part number has now been replaced by the CTS-UFHN Cam Test Stand Narrow Universal Flat Tappet.

Part Number: CTS-UFHN Cam Test Stand Narrow Universal Flat Tappet with

Indexed Holder, with a 2.0" long x .250" wide flat face. This setup lets you measure most any flat

tappet cam and simulates followers up to 2.0 inches in diameter (the length of

the precision .250" plate held perpendicular to the cam). This can also

be used to measure the position of keyways (with CTS-TDCM2 .250"

magnet in keyway), or dowel pins. Note the indexing screw at front

of lifter bore bracket, and indexing rod which slides in the slot of the lifter

bore to keep things perpendicular to the cam. The narrow, flat edge allows

the follower to ride on timing pins which may stick out of a cam just a few

millimeters. Measuring a timing pin lets you determine the timing of the

cam if you know the location of the pin, or lets you measure the location of a pin

with respect to a cam centerline.

![]() for a movie showing how to locate a dowel pin using the now obsolete "TDC

bridge". Using

the CTS-UFH instead of the bridge would be very similar.

for a movie showing how to locate a dowel pin using the now obsolete "TDC

bridge". Using

the CTS-UFH instead of the bridge would be very similar.

Part Number: CTS-ML Locating magnet, keeps cam aligned accurately on V blocks. Flip down and

its out of the way. Flip up and it keeps cam turning true on the

stand. Magnet slides out of the way if it encounters a dowel pin.

Kit includes magnet, shoulder screw, washer, nylon spacer, template for locating

6-32 hole you drill and tap, and instructions. ![]() for instructions.

for instructions.

Part Number: CTSUR750 Universal .750" roller follower, lets you measure any cam designed for a

.750" diameter roller (typical of most, US V-8 aftermarket rollers).

Sized for a GM .842" ID lifter bore adapter, this includes the follower

only and not the lifter bore adapter.

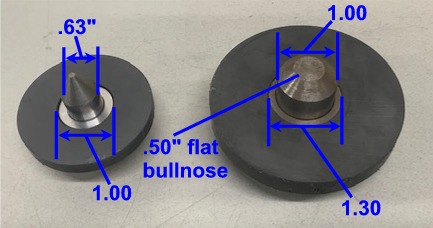

click images to enlarge, tip not included

click images to enlarge, tip not included

Part Number: CTS-PTF

Precision Tip Follower provides a method to measure a cam with a very small

radius follower, but avoid side loading wear on the linear encoder (lift

sensor). Side loading can be quite high when measuring lobes with very

steep ramp rates. The follower comes with 4-48 threads to accept our

CTS-PT, or probes you can provide.

Note: Current design may look slightly different but function the

same.

click images to enlarge

click images to enlarge

Part Number: CTS-VBC V-Block

Clamp, holds short cams firmly on the V Block, shown installed with Adjustable V

Block. Short cams with the linear encoder attached to the end will tend to

tip off the V Blocks, and this clamp holds the cam in place. It has a

soft, nylon tip to provide smooth rotation and not damage the journal.

click images to enlarge

click images to enlarge

Part Number: CTS-RHD8 Rotary Encoder mount we developed for the

Harley Davidson Milwaukee 8 cams. It is steel and has somewhat higher

precision than the "Flat Mount" below, and can be more

universal. It has a steel tapered pin of .250" (6.4 mm) diameter, and

a magnet .375" (9.5mm) ID and .750" (19mm) OD . So if your cam

has a small hole in the end of less than .250" and an ID of less than

.650" (16.5mm) and an OD of more than .400" (10mm), this will work

well for you.

Standard Flat Mount 1.00"

magnet

Small Flat Mount .75" magnet

click images to enlarge

click images to enlarge

Part Number: CTS-RMF and CTS-RMFI

Cam Test Stand Rotary Encoder Flat Mount and Insert will attach the rotary

encoder to cams without a flat face on one of the ends. These are

typically motorcycle cams. ![]() for instructions.

for instructions.

Click on image above to understand the information we need for this flat mount

insert. The magnets come in 2 sizes, small is .38" ID with .750"

OD, or standard is .50" ID with 1.00" OD. We can make the

inserts to most any size, to accommodate either straight or tapered holes in the

end of your cams. In the picture of the Small Flat Mount above, the insert

is quite small, a 5.5 mm diameter. You need to specify the outside diameter and thickness

of the insert (green in picture). The insert does not need to fit perfectly, so

specify an outside diameter slightly smaller than you think you need. If the

rotary encoder is slightly off center, it does not have a significant effect on

the data.

click images to enlarge

click images to enlarge

Part Number: CTS-RECM Rotary

Encoder Chuck Mount, requires the CTS-EVB above to provide

clearance. This mount for the rotary encoder can work for cams with very

large or very small centering holes, or very small journals on the ends of the

cam. This chuck can grab either and outside diameter or inside diameter,

and can be more universal than the magnetic mounting methods we offer. The

jaws can open up to accommodate cam journals as large as 2.80" or larger.

Jaws flipped to grab an inside diameter can go as small as .875" inside

diameter.

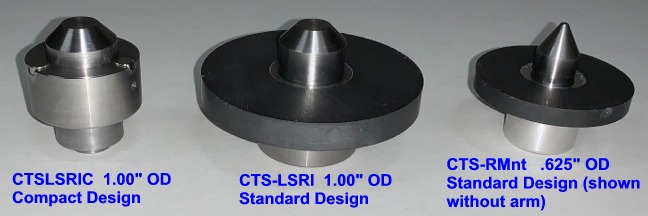

Part Number: CTS-LSRI and CTSLSRIC Larger diameter rotary encoder index

(1.00") and

magnet/bore to accommodate cams with larger than .625" holes in their ends.

The Compact Design allows for more clearance around index, so it fits on the Cam

Test Stand better for more cam designs.

Here's some measurements so you can decide which may work better on your

cams. The ID of the part of the cam to locate the center (pointy part)

should be smaller than the OD of the centers shown in this picture. The OD

of the end of the cam can not be smaller than the ID of the magnet.

Otherwise there is no magnet to attach to the end of the cam. The CTSLSRIC

compact design has the magnets closer to the 1.00" center compared to the

larger design shown in this picture. The 1.30" measurement is

approximately 1.10", so it can accommodate a cam with a smaller OD.

click images to enlarge

click images to enlarge

Part Number: CTS-REBF Magnetic rotary encoder mounting adapter for

Briggs & Stratton flatheads, with .75" diameter journals. The

Briggs cam in the picture is being measure with the CTS-REBF and our Universal

Flat follower (CTS-UFN). The standard V Blocks typically provide enough

clearance for the gear on the cam. To accurately measure the intake lobe

with the "EZ Pull" compression relief on the intake closing ramp, you

need to set the Option of "Cam Lobe may have 2 bumps". This

option is only in the Plus or Cam Grinder version of the software.

![]() for

a movie "Installing-rotary-encoder-magnetic-mount.mp4" showing

how to install the rotary encoder with magnetic mount on the end of a typical

camshaft.

for

a movie "Installing-rotary-encoder-magnetic-mount.mp4" showing

how to install the rotary encoder with magnetic mount on the end of a typical

camshaft.

Part Number: CTS-LEH Linear Encoder lift handle, provides an easy way

to lift the linear encoder probe. This is especially handy when not using

a follower, but measuring the lobe directly for the Virtual Follower feature.

Part Number: CTS-PT Precision 0.047 inch diameter tip for linear encoder. This is required

for measuring very aggressive, inverted flank (concave) profiles.

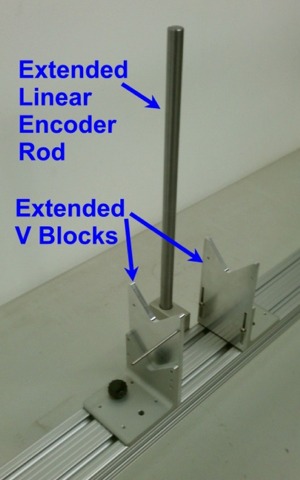

Part Number: CTS-EVB Extended Height V Block Kit, includes 2 V Block

Extensions (requires "New Style V Block

(2010)" shown above) and extended length Linear Encoder

Part Number: CTS-AVB Adjustable V Block lets you level out the cam

when the journal on one end can be significantly different than the other

end. Note: A slight difference in cam height from end to end (slight

slope of the camshaft on the stand) is not critical for most measurements,

because the encoder is "zero'd out" by the software for each lobe

measurement.

Part Number: CTS-MC This option adds a motor to turn the cam at a

slow, controlled rate, and for mounting the cam "on centers".

This can provide for more accurate measurements, especially for acceleration and

jerk measurements.

click image to enlarge detail of pointed center for CTS-MC to see how well it would work

for your particular cams. Center is .900" diameter with 60 deg taper.

click image to enlarge detail of pointed center for CTS-MC to see how well it would work

for your particular cams. Center is .900" diameter with 60 deg taper.

Part Number: CTS-RECA This Rotary Encoder Cam Pro Plus Adapter plate

lets you mount the Performance Trends rotary encoder into the Cam Pro Plus

mounting bracket. This provides more options to ensure you can completely

convert your Cam Pro Plus hardware to Performance Trends software and

electronics.

click image to enlarge

click image to enlarge

Part Number: CTS-RMnt

Rotary Encoder Mounting Kit lets you magnetically mount and center the

rotary encoder to the end of your cam. This is a popular option for

customers who want to build their own stand with V blocks.

click images to enlarge

click images to enlarge

Part Number: CTS-LEM linear encoder mounting arm CTS-LBM lifter

bore mount CTS-LBC lifter bore (custom size) CTS-LESR linear

encoder sensor rod These can be ordered as replacement parts

or for you to adapt to your own DIY cam test stand.

click image to enlarge

click image to enlarge

Part Number: CTS-xxHD Heavy

Duty Cam Test Stand option, where xx is the length of the stand in inches.

This option is for very long, or very large (journals over 3" diameter), or very heavy cams which can weigh up to 100 lbs or

more. It includes larger base extrusion, roller bearings instead of V

blocks, and other heavy duty brackets.

Part Number: CTS-WOS This is a complete test stand, but without the

stand. This is a good choice for people who want to build their own

hardware. The system includes the precision linear and rotary sensor,

Black Box II logger, and basic Cam Analyzer software. Please note that

building a cam test stand is not as simple as you may first think. We have

learned over the years the items which are important to make the stand both easy

to use and keep the measurements as accurate as possible.

Ask about other custom options which include:

- 38 and 48 inch long stands for cams up to 34 or 44 inches respectively. Combined with the CTS-xxHD Heavy Duty Cam Test Stand option, we've made stands over 100" long.

- Lifter Bore Adapters to accommodate various lifter diameters (Note lifter diameters greater than approximately 34 mm require a special, larger lifter bore bracket.)

![]() to return to the main Cam Analyzer page.

to return to the main Cam Analyzer page.

![]() for prices of the

Cam Test Stand and accessories.

for prices of the

Cam Test Stand and accessories.

![]() for narrated demo movies explaining program features

for narrated demo movies explaining program features

![]() for info

on Cam Test Stand Assembly

for info

on Cam Test Stand Assembly

![]() for tips on producing repeatable results

for tips on producing repeatable results

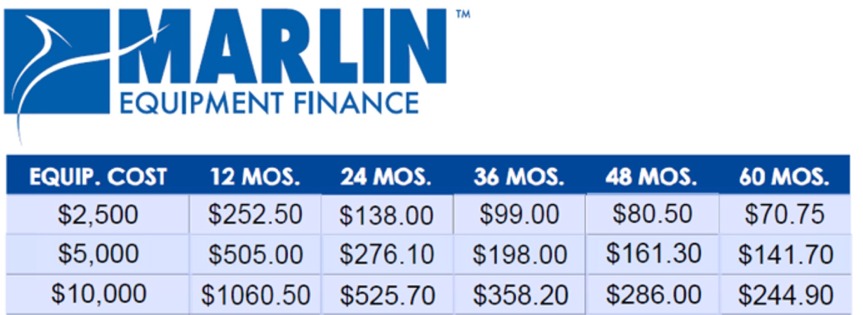

Financing can make your larger investment very affordable. Here's a typical rate schedule (June 2018).