Performance Trends, Inc.

Producing Quality Computer Tools for Racers and Engine Builders since 1986

If you're a racer, race enthusiast, or engine builder with

engineering talent,  for info on joining our team.

for info on joining our team.

Quick Cam Checker to Measure Cam Lift, Duration, Centerlines, etc. Quickly on Engine

As Seen on TV's Motorhead Garage

![]() to view clip of show

to view clip of show

![]() for

a movie showing the Quick Cam Checker in action

for

a movie showing the Quick Cam Checker in action

![]() for

results from track tech inspection of 604 Crate Motors

for

results from track tech inspection of 604 Crate Motors

New, compact, heavier duty bracket for lift sensors, 2017.

The Quick Cam Checker lets you check timing on your cam quickly and easily, without having to find TDC or set up a degree wheel. Using a smart microprocessor and inexpensive sensors, you can find centerlines while just cranking the engine over with the starter. Other data like lift, duration at .050", etc are included. No computer is needed, but it can send results to the free Windows software via the USB cable.

Features include:

- Two (2) lift sensors with .0004" measurement resolution with mounting bracket.

- Rotary sensor with 0.1 degree resolution, can be mounted to most any component or belt which rotates with the engine. Self calibrating with mounting bracket.

- Pressure sensor for spark plug hole, with 14 and 18 mm threads.

- Microprocessor with backlight, large digit, LCD display, rechargeable battery, and USB connection.

- Free Windows software for uploading the recorded data for storing, analyzing, printing, graphing, etc.

- New software features (v1.1 A.012 or later) include overlay graphs, and reports of duration and events for both profiles, and a baseline test (if selected) and the difference between the tests (if selected).

- Output includes centerlines, lobe separation, lift, duration/opening/closing at most any lift you set before the test.

Note: At this time, the system only works well when the engine is turning continuously, like when cranking it over with the starter. We're still working to make the system work accurately on the engine stand, when you are barring the engine over by hand.

Quick Cam Checker Software

Quick Cam Checker Main Screen

![]() for

an example of an Export File of Cam Checker Data which displayed All Data

for

an example of an Export File of Cam Checker Data which displayed All Data

Recent additions to the software (v1.1 A.012 or later, and then v1.1 A.014) include the ability to do overlay graphs with a test you have designated as a "baseline" for comparison. This is very handy if you are checking to see if the cam in 1 vehicle is matching the cam in another, like for track inspection. The graph below shows the baseline test graphed in black called "4 Test 4 repeat" with the current test being called "7 Test 1". You can see that both profiles are nearly identical, which is very useful for track inspection. Also shown are many new Graph options letting you:

- Change the graph scale. You will notice the scale of screen below shows profiles much larger than the standard scale of earlier program, shown in picture above.

- Change the thickness of the lines.

- Whether to include a baseline graph or not, and picking a test to designate as the baseline.

- Whether to include a report of the duration and events for 1 or both graphs at .050" lift increments, and include a table showing the differences between these 2 tables (as shown in picture below).

- Advance or Retard the current profile over the Baseline

- Ask the program to find the amount of advance or retard to find the closest agreement between the profiles. This makes it much easier to see if 2 profiles match, and the difference is only some stretch in the timing chain.

- Profiles can be imported by the Cam Analyzer program, v4.3 or later.

- GM 602 and GM 604 crate motor example profiles for comparison already in the software. Mark one of these cam profiles as the Baseline and then comparisons to any 602 or 604 crate motor cam you measure is very easy. Very handy for track inspections.

Click here for page 13 from User's Manual showing Cam Advance features

Click here for page 13 from User's Manual showing Cam Advance features

Quick Cam Checker Overlay Graph with Baseline, and Showing additional

Graphing Options (baseline profiles drawn in black)

Quick Cam Checker Overlay Graph Report

Comparison of Baseline 604 profile provided with Cam Checker (black) with

604 profile just measured with Cam Checker (color)

Track Tech Inspector Experience

Chad Smith, a licensed IMCA tech inspector, was good enough to share many of his data files and experience with us. Here's some screen captures from Chad's results with some explanations. Note that some records were not of 604 Crate Motors, and have been crossed out in blue in the table. We have also shrunk down the first column with "Record" names like engine #, racer name, etc to protect people's privacy. Typically this column is wider to display it's info clearly.

With his experience, Chad developed his own 604 Baseline from one of his tests, run #12. He said it agrees better with other legal engines he's tested than the 604 baseline provided with the Quick Cam Checker software. Here's a graph comparing his Baseline to the 604 Baseline provided in the QCC software. You will notice his Baseline's lift is slightly less and both lobes are slightly retarded.

Here's 3 typical comparisons of cams that passed tech inspection (the red and blue graphs) graphed over his typical baseline in black. The first graph shows where the Run Number is so you can refer to the table if you want exact durations, lifts, centerlines, etc.

Here are 2 graphs for a cam that did not pass tech inspection. These are 16 and 17 in the table. Runs 14 and 15 were also done of this same cam. The cam was pulled and tested on a complete cam test stand and verified to be out of spec, and the racer disqualified.

Runs 9, 10, and 11 of another engine raised some eyebrows, but not to the point of pulling the cam for further testing.

Accessories:

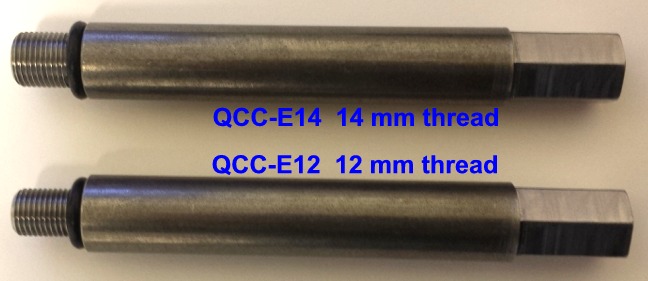

On 4 valve or hemi engines with plugs located deep inside the valve covers, you may need an extension for the pressure sensor.

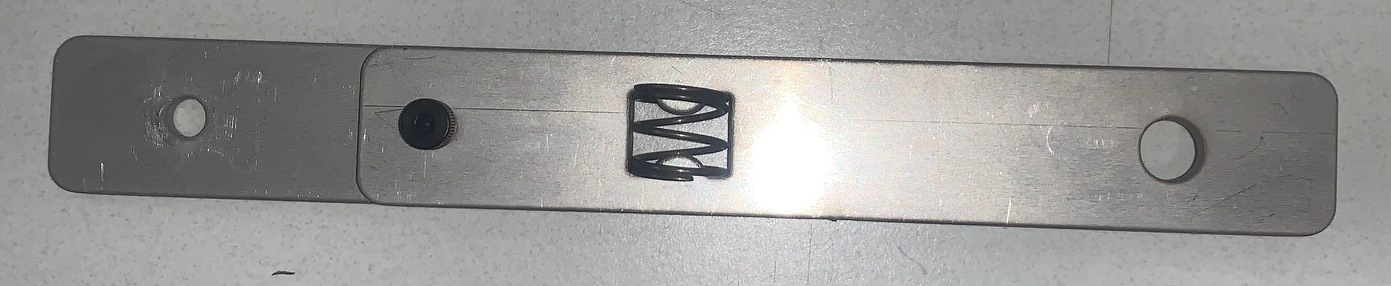

QCC-CM6 Adapter to mount the Quick Cam Checker's valve lift sensors on the 602, 603, 604 GM Chevy crate motors. (This bracket also fits LT1 "center bolt" heads on 92-97 Camaros and Corvettes.) Remove the rocker arms and it quickly mounts directly on the pushrods for better accuracy, eliminates the errors of hydraulic lifter leak down or a changing or unknown rocker ratio and/or lash. This is a very handy tool for track tech inspectors for the 602, 603, 604 GM Chevy crate motors.

We also have brackets to fit the GM LS1 "Cathedral Port" heads and the GM LS3 Rectangular Port heads, part numbers QCC-CMLS1 and QCC-CMLS3. If you need to test both motors, you can purchase either bracket assembly and just purchase a mounting plate for the other style head and save significant cost.

(Lift sensors not included with bracket.)

(Lift sensors not included with bracket.)

QCC-PK QCC-PKC QCC-PK5 Universal adapters to mount the Quick Cam Checker's valve lift sensors on most pushrods to measure tappet lift directly from the cam. It uses the standard mounting hardware, which (unfortunately) has more flex than the QCC-CM6, but provides a much less expensive alternative. If you design your own more rugged mounting hardware for your particular engines, you will have a great system for measuring tappet right off the pushrod.

The "Pushrod Kit" comes with 2 precision adapters and 2 helper

springs, and is affordably priced. The adapters snuggly fit on the tip of

the sensor, securely hold the spring in place and provide a radiused pocked for

the pushrod. The helper springs provide more force to keep the

lifter in contact with the cam lobe as you crank the motor with the

starter. Adapters are available for either standard or cup style

pushrods. Black ones on the right are our new "extended"

adapters to better align themselves on the pushrods.

QCC-PKM QCC-PKT

Universal adapters to attach either a strong rare earth magnet or 4-40 threads

to the Quick Cam Checker's valve lift sensors. The magnet adapter provides

a secure method to attach the lift sensor to a steel valve spring

retainer. The threaded adapter lets you come with your own adapters or

extensions.

Options Handy for Measuring Cam on Engine Stand:

![]() for

youtube movie of testing a cam on the engine stand

for

youtube movie of testing a cam on the engine stand

Here's pictures of some of these accessories on the engine when measuring a cam on an engine stand.

QCC-RRS1 10 turn rotary sensor, needed for when the engine is rotated by hand, with starting and stopping.

QCC-RWL Large 5.25" diameter rotary drive wheel which can work well with QCC-RRS1. This is needed if the diameter of the engine component is larger than approximately 4". For components less than 4", the standard 2.6" drive wheel (pn QCC-RW) will work fine, pictured on the right.

QCC-LSEY Lift sensor and enclosure to measure piston position, the same as a replacement sensor for measuring lift. User will have to fabricate the bracket for mounting the sensor. See typical mounting above about 3 pictures above.

QCC-SPB Spring Loaded Bracket for mounting the rotary sensor on solid engine components like a damper or pulley. Without spring loading, it is difficult to put enough pressure on the rotary sensor drive wheel to keep if from slipping. Note: If you mount when rotary sensor on a belt, there is typically enough spring effect in the belt that this is not needed.

QCC-SRP Strain Relief Package, to reduce wear and tear on the USB connector in the logger from frequent plugging and unplugging.

Obviously we do not have brackets for every engine, so customers will build their own custom brackets. Here's what Aleksei Noskov from Estonia built to do tech inspection for UIM GT30 class motorboat racing.

More Info:

![]() for Users Manual and installation

tips.

for Users Manual and installation

tips.

![]() for

a movie showing the Quick Cam Checker in action

for

a movie showing the Quick Cam Checker in action

To Order:

Call 248-473-9230. Visa or Mastercard accepted.

Electronics like Quick Cam Checker have a limited 1 year warranty.